Explore Our Methodology

Our Process Flow

Step 1

Project Request

Specifications

Quick Analysis

Project Offer

Order Process

Step 2

Analyze

Economical Concept

Indication Of Possible Problems

Troubleshooting

Mold Design

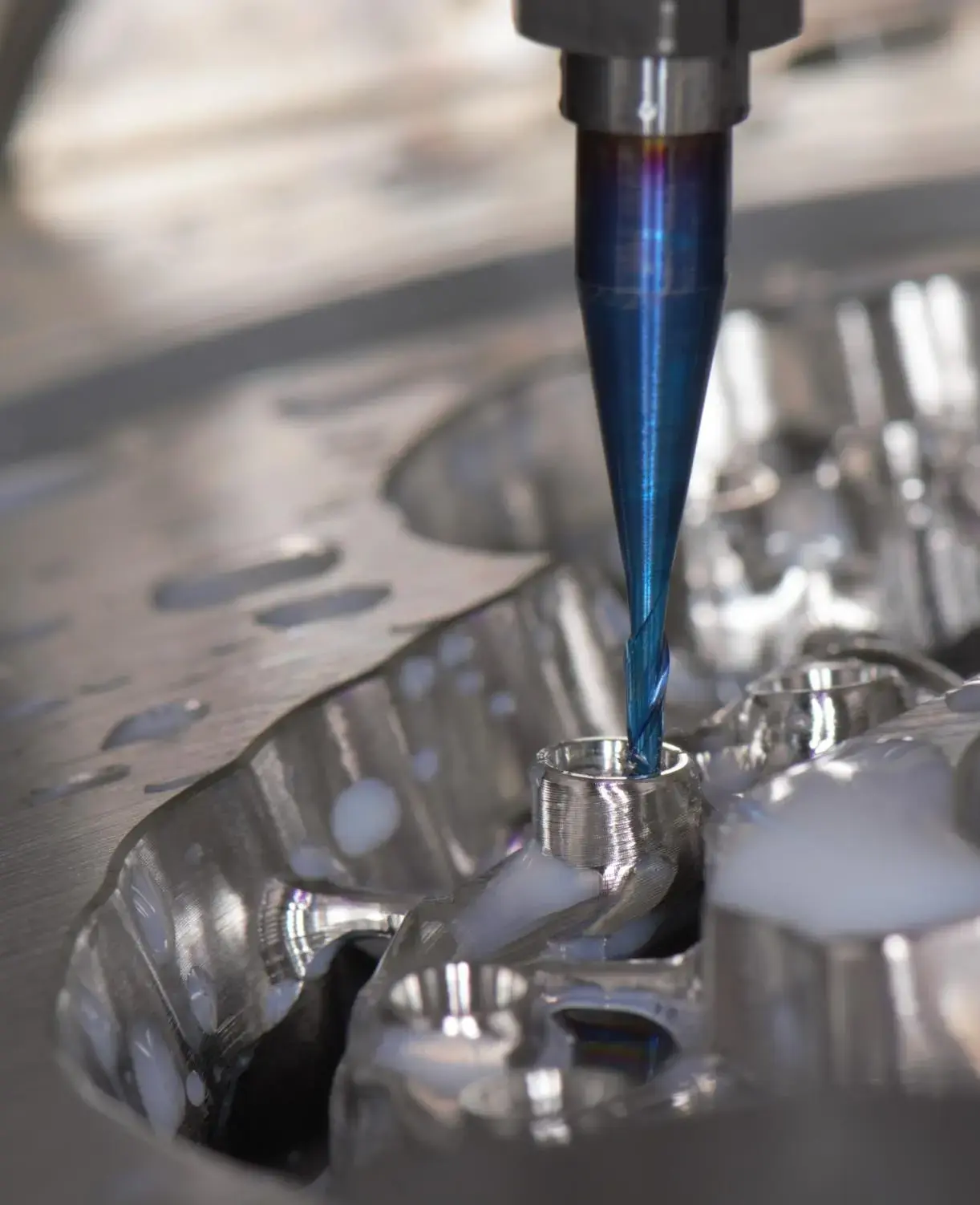

Step 3

Design Release

Material Procurement

Start Of Production

Tool Assembly

T1 Initial Sample

Step 4

Check The First Sample

Initial Sample Test Report

Dispatch Of The Initial Samples For Approval

Corrections If Necessary --> T2/t3

Step 5

Shipping Process

Customs Clearance

Tool Commissioning

Serial Production

Step 6

End of Process

Our Business Partner

Thomas Feiertag -

CAD Konstruktion & Entwicklung

At ASOME-TEC, we are proud to collaborate with Thomas Feiertag, a seasoned expert in CAD design and product development. With over 25 years of experience in mechanical engineering, Thomas brings deep technical insight and precision to every project.

His company, based in Germany, specializes in:

- 3D CAD design for mechanical components and assemblies

- Product development from concept to production-ready solutions

- Reverse engineering and optimization of existing designs

- Part optimization guided by DfM principles

- Part removal concepts (also referred to as ejection strategies)

- Prototyping and technical documentation

Thomas’s approach is rooted in practical engineering, with a strong focus on manufacturability, cost-efficiency, and innovation. His contributions have been instrumental in helping clients across industries—from automotive to industrial equipment—bring their ideas to life.

Our partnership with Thomas Feiertag strengthens our ability to deliver tailored, high-quality engineering solutions that meet the evolving needs of our clients.

Your Project Is In Good Hands

Our Promise To You

- Competent Specialist Advice

- Delivery According To Your Specifications

- Effective And Process-reliable Injection Molds

- Adherence To Deadlines In The Project Plan

- Regular Project Reports

- Uncomplicated Project Processes